Your Cart is Empty

Worldwide Shipping

Worldwide Shipping

Worldwide Shipping

Brand Name: NoEnName_Null

Origin: Mainland China

Structure: Deep Groove Ball

Coatings: Antirust Oil

Material: Steel

Torque Capacity: 17x26x5 MM

Surface Roughness: Ra 0.05

Model Number: 6803 2RS 17*26*5mm 10Pcs

Certification: RoHS

WHAT IS A THIN SECTION BEARING?

Thin Section Ball Bearings were developed for applications where space limitations are of the utmost importance.

As the name implies, the difference between the inside and outside diameters of the rings has been minimized or thinned out.

Of course this comes at a price by compromising load capacities.

However, these bearings can still accommodate a relatively light radial thrust or combined loads.

6700 Series - Metric dimensional series for very limited space applications and very light loads

6800 Series - Metric dimensional series for limited space applications and light loads

63800 Series - A hybrid between the 6800 and 6900 Series with the load capacities of the 6800 series but the width of the 6900 series.

6900 Series - Metric dimensional series for limited space applications and heavier loads

TECH DEATAILS

Item: 6803-2RS

Structure: Thin Section Ball Bearing

Material: 52100 Chrome Steel

Type: Rubber Sealed ( RS )

Bore Dia (d): 17 mm

Outer Dia (D): 26 mm

Width (B): 5 mm

Clearance: C0

Grades: ABEC-1

Lubrication: With Grease

Quantity: 1 Lot = 10 PCS

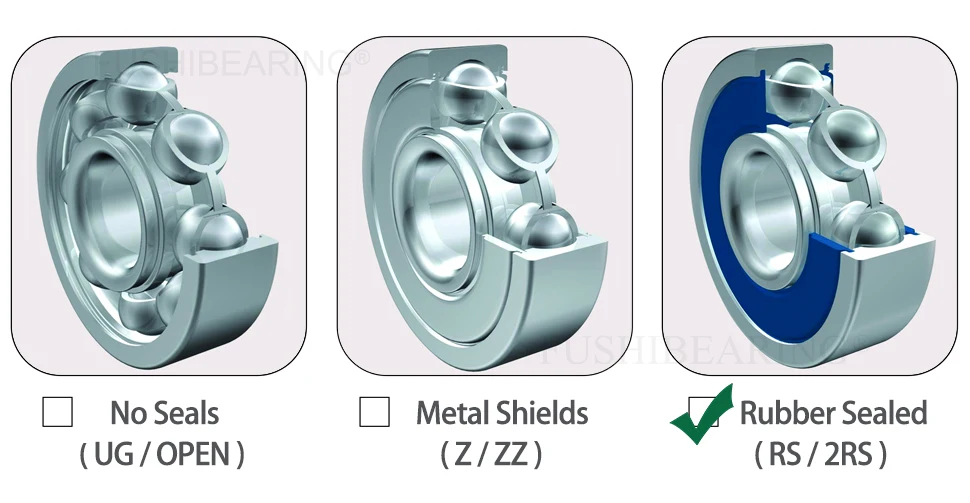

This Bearing Structure

Standard Type: A ball bearing is composed of an outer and inner ring, balls, seal and a retainer.

This Bearing Cover

Compared to the open type, the shielded and sealed bearing types provide better protection from contamination and grease leakage.

They are selected based on the application type and environment.

This is 2RS double rubber sealed.

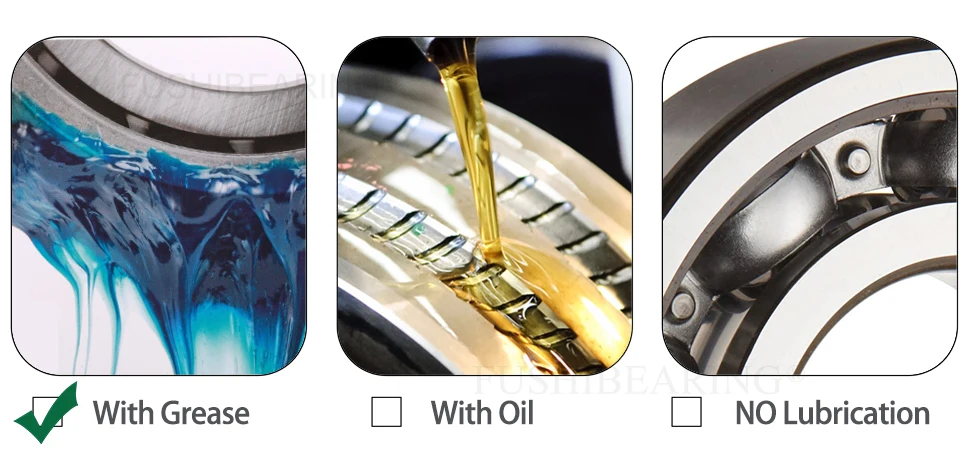

This Bearing Lubrication

One of the most important elements required for the effective function of bearing arrangements is correct lubrication.

The lubricant separates the metallic bearing surfaces and thereby reduces friction, preserves the steel parts and acts as an additional barrier against the entry of contaminations or impurities into the bearings.

This Bearing Cage

Retainers keep the balls separated and equally spaced.

Retainer types are set based on the bearing size but can be selected based on the required performance.

This is made of steel ribbon.

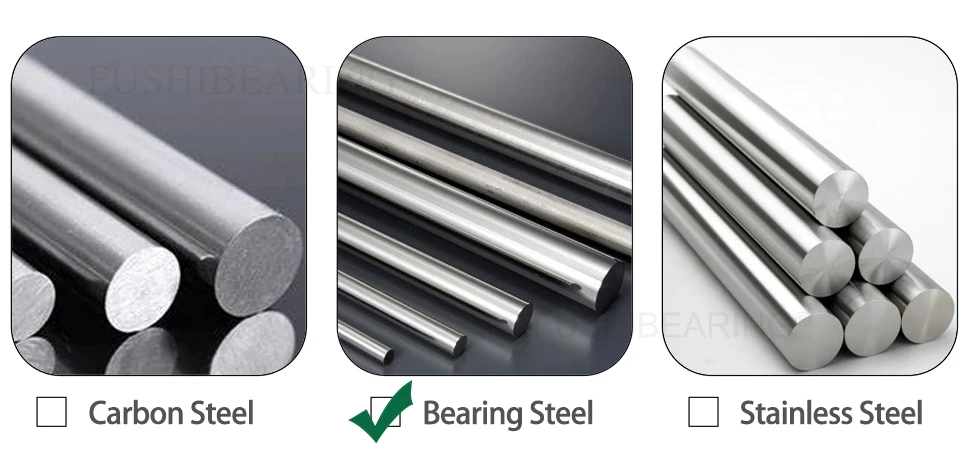

This Bearing Material

The most common material used to produce the load carrying components in roller bearings is 52100 chrome steel (bearing steel).

The typical surface hardness for bearing components made from this material ranges from 60- 64 on the Rockwell hardness C scale (Rc).

This Bearing Balls

Due to this usually very small contacting area ball bearings have less frictional resistance and are more suitable in high speed applications.

This is made of steel.

This Bearing Clearance

The term “clearance” is briefly described as the distance that bearing components may move relative to each other at physical extremes.

CN (C0) “normal” clearance

This clearance group is defined as the standard.

Thus CN is not marked on the bearings. Historically the standard clearance was designated as “C0“.

C2 clearance range smaller than CN

C3 clearance range larger than CN

This Bearing Grade

Executive standard:

GB/T 307.1-2005

Rolling bearings Radial bearings Tolerance

MORE BEARINGS DETAIL

FEEDBACK & OUR SERVICE

Collections: Recommended products (Seguno)

Type: Unknown Type

You can use this popup to promote newsletter signups, but that's not all! You could also omit the form and include action buttons linked to your pages and products instead. Or, use the popup to present an 'agree-to-terms' message that must be accepted before a visitor enters your shop!